The Principle

The Flo-Master employs a very simple, volumetric method to draw liquids and other low viscosity products such as oils or juices directly from a tank or drum, eliminating the need for a hopper. This model and also be used as a metering pump to dispense a controlled volume.

How it works

1. The piston takes an intake stroke drawing product from the hopper through the lower check valve while closing off the upper check valve. 2. On the discharge stroke, the piston pushes the product from the cylinder through the upper check valve to the nozzle, while closing the lower check valve.

Operation

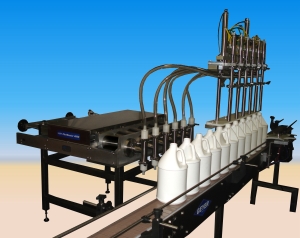

The intake tubing of the filler can be immersed directly into the product tank or can be connected directly to a gravity fed manifold or the bottom discharge fitting of tank or kettle. The volume of fill is adjusted to the desired setting. Empty containers can be manually placed or fed automatically on the filler′s conveyor. The automatic container indexing system (air cylinder or starwheel) will stop the row on containers momentarily for filling. Depending upon the type of product and container being filled, the containers can be filled from top down, or by the optional diving nozzle mechanism for ″bottom up″ fill. Nozzles have a positive cut-off mechanism to stop the flow of the product cleanly after each fill cycle. Once in operation, the machine operates automatically and requires minimal operator assistance. Production fill rates depend on the type product being filled, container volume and size of the container′s opening. In general, fill rates run from approximately 8 to 25 cycles per minute, per cylinder. accuracy of fill is plus or minus ½ of 1 percent by volume for each fill.

Standard Features

Frame construction: welded and polished, all stainless & non-corrosive materials, Product contact parts: 304 s.s. and food grade plastics, air cylinders to drive pistons, air logic, (1) set of s.s. cylinders and pistons, (1) set of s.s. filling nozzles on adjustable nozzle bracket, s.s. check valves, flexible tubing, s.s. conveyor with variable speed drive and controls, automatic container indexing system, no container detector on conveyor, leveling feet, safety guarding, on-off controls.

Optional

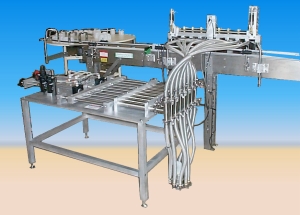

Diving nozzle mechanism, neck capturing device, automatic drip pan, wash down motors & controls, cross index container handling, interchangeable cylinders & nozzles, 316 s.s. or all plastic product contacts, product infeed manifold, heated tubing, etc.

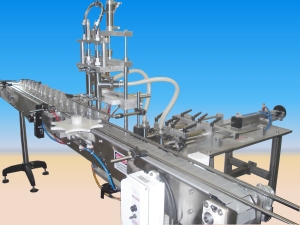

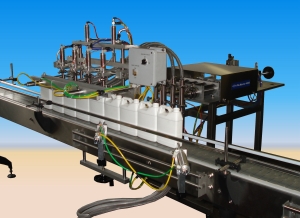

Models

Click on image to enlarge, link will open in a new window.

| Home | Products | Parts & Service | Info. Request | contact Us | Videos |