1 Cylinder Fillmaster Jr. table top filler

Fills up to 30 cups per minute from 1/2 oz. to 12 oz., viscous and chunky products. All stainless, USDA/FDA construction. Options include Interchangeable fill nozzles, floor stand, positive cut-off nozzles, diving nozzles, conveyors, heater for hopper, etc.

1 Cylinder Fillmaster 5000 on floor stand with 4 ft. container track and container lift

Fills up to 30 cups per minute from 1/2 oz. to 32 oz., viscous and chunky products. All stainless, USDA/FDA construction. Options include Interchangeable fill nozzles, floor stand, positive cut-off nozzles, diving nozzles, conveyors, heater for hopper, etc.

We also offer other models that will fill up to 2.5 gallon size containers.

Model 970 Table Top Lid Presser

Very simple unit to press on hand placed lids. Presser head is domed to push center of lid first, then outside of lid to push out air from under lids. All pneumatic, comes with foot pedal. Will handle all size lids.

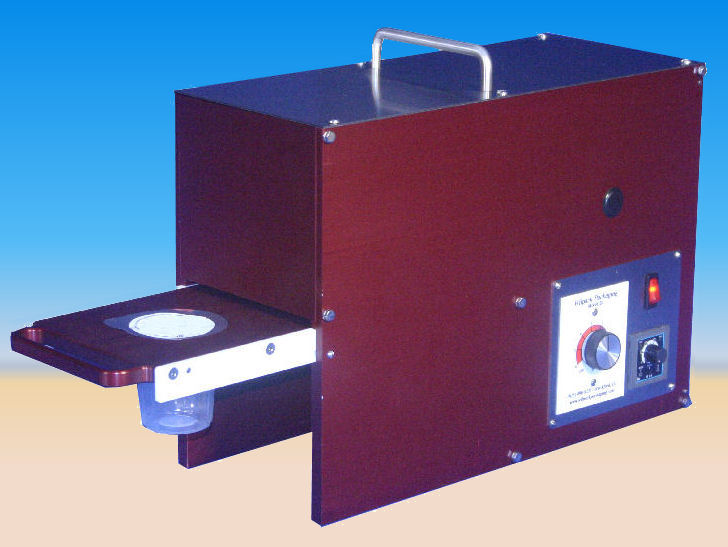

Table Top Foil Sealer

Place the filled cup in the holder, place a foil seal on top of the cup, push the cup into the unit, the seal head automatically will lower and seal the foil seal to the top of the cut. Works with die cut foil seals. Interchangeable fixtures for different diameter cups are available. 110 volt, 1 phase.

Table Top Plastic film Sealer

Place the filled cup in the holder, this will activate the unit and the cup will move under the sealing area. The seal head automatically lowers seals the film to the cup, and cuts it to size. The film spools automatically advance for each seal. 110 volt, 1 phase.

Indexing Conveyors

Automate your cup packaging line by adding a conveyor. This type of conveyor has been designed to handle tapered style deli cups. Also works with standard glass and plastic bottles as well.

This unit is also known as an intermittent motion conveyor. Cup can be placed by hand (or by a cup denester) at the feed end. The cups move 1 or 2 at a time to the filling zone. The conveyor can have a container lift table at the fill zone (shown in photo) to

bottom up fill viscous products. A foil or film sealer as well as a

lid placer and presser can be added

(see automatic cup filler/sealers).

Model RCS15 Foil Sealer

The turret of this unit is turned one station at a time by the operator. A filled cup is placed on a platform that lowers it into the turret. It is moved to the foil placing station where this unit will place the foil onto the cup. The turret is moved one station to the next station where the heating head lowers and seal the cup. Sealed cups are removed at the final station where they are replaced with a new cup. Adapters are available to handle various diameters up to 5 ″.

Fillmaster 5000 with Model RCS15 Foil Sealer

By adding a Fillmaster 5000 piston filler, this unit will fill and foil seal cups at speeds up to 20+ per minute, depending upon the product and size and size of the cup.

| Home | Products | Parts & Service | Info. Request | contact Us | Videos |